Modern automotive systems rely heavily on sophisticated sensor technologies to monitor everything from engine performance to environmental conditions. These critical components face constant exposure to moisture, dust, temperature fluctuations, and pressure variations that can compromise their accuracy and longevity. The MicroVENT ePTFE membrane has emerged as an essential protective solution, offering unparalleled barrier properties while maintaining the breathability required for optimal sensor function. This advanced membrane technology represents a breakthrough in automotive sensor protection, ensuring reliable performance in the harshest operating conditions.

Understanding ePTFE Membrane Technology

The Science Behind Expanded Polytetrafluoroethylene

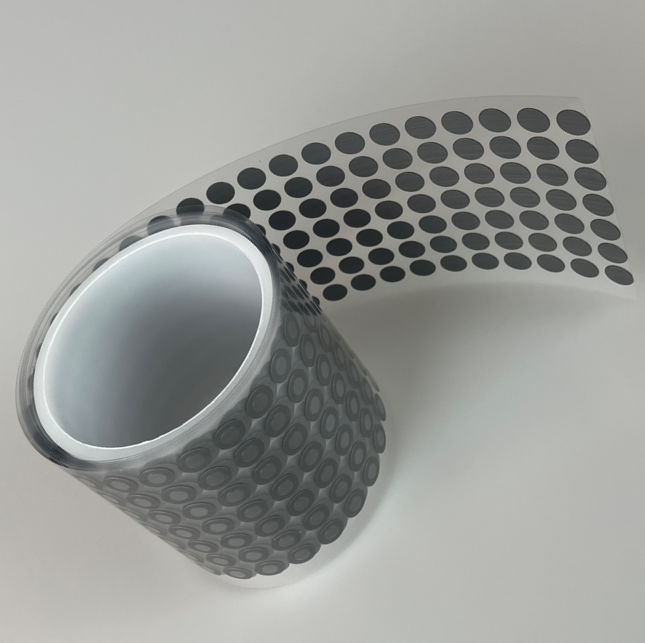

Expanded polytetrafluoroethylene represents one of the most advanced materials in membrane technology. The unique molecular structure of ePTFE creates a microporous network that allows gas molecules to pass through while blocking liquid water and contaminants. This selective permeability makes the MicroVENT ePTFE membrane ideal for automotive applications where sensors require pressure equalization without compromising protection. The manufacturing process involves stretching PTFE to create billions of microscopic pores, each precisely sized to achieve optimal performance characteristics.

The hydrophobic nature of ePTFE ensures excellent water resistance while maintaining breathability. This characteristic proves crucial in automotive environments where temperature changes create pressure differentials that must be equalized to prevent sensor malfunction. The MicroVENT ePTFE membrane maintains its structural integrity across extreme temperature ranges, from sub-zero winter conditions to high-heat engine compartment environments. This thermal stability ensures consistent performance throughout the vehicle's operational lifetime.

Microporous Structure and Performance Benefits

The microporous architecture of the MicroVENT ePTFE membrane provides exceptional filtration capabilities while allowing rapid gas exchange. Each pore measures approximately 0.2 microns in diameter, small enough to block water droplets and particulate contaminants while permitting air molecules to flow freely. This precise pore structure eliminates the condensation buildup that commonly affects automotive sensors in humid conditions. The membrane's high porosity ensures minimal pressure drop across the barrier, maintaining sensor responsiveness.

Chemical inertness represents another critical advantage of ePTFE technology. The MicroVENT ePTFE membrane resists degradation from automotive fluids, road salts, and aggressive cleaning chemicals commonly encountered in vehicle applications. This chemical stability prevents membrane deterioration that could compromise sensor protection over time. The material's non-reactive properties ensure compatibility with various sensor housings and mounting configurations without material compatibility concerns.

Critical Protection Functions in Automotive Applications

Moisture and Water Ingress Prevention

Water infiltration poses the greatest threat to automotive sensor reliability, potentially causing short circuits, corrosion, and measurement errors. The MicroVENT ePTFE membrane creates an impermeable barrier against liquid water while allowing water vapor to escape, preventing condensation accumulation inside sensor housings. This vapor transmission capability proves essential for maintaining dry internal conditions during temperature cycling. The membrane's hydrophobic surface tension prevents water droplets from penetrating the microporous structure, even under pressure washing conditions.

Humidity management becomes increasingly important as automotive sensors become more sensitive and compact. The MicroVENT ePTFE membrane facilitates moisture vapor transmission, allowing trapped humidity to escape while preventing external moisture ingress. This bidirectional moisture control maintains optimal humidity levels inside sensor enclosures, preventing the condensation-related failures that plague unprotected sensors. The membrane's consistent permeability ensures reliable moisture management across varying atmospheric conditions.

Contaminant Filtration and Barrier Properties

Road dust, salt spray, and airborne particulates constantly threaten automotive sensor accuracy and longevity. The submicron pore structure of the MicroVENT ePTFE membrane effectively filters these contaminants while maintaining breathability for pressure equalization. This filtration capability extends sensor life by preventing abrasive particles from reaching sensitive components. The membrane's surface properties resist fouling, maintaining filtration efficiency throughout extended service intervals.

Chemical vapors and automotive fluids present additional contamination risks that can interfere with sensor operation. The inert nature of the MicroVENT ePTFE membrane provides excellent resistance to hydrocarbon vapors, brake fluids, and other automotive chemicals. This chemical barrier protection prevents sensor drift and calibration errors caused by chemical interference. The membrane's stable properties ensure consistent barrier performance despite exposure to harsh automotive environments.

Pressure Equalization and Sensor Performance

Managing Thermal Cycling Effects

Automotive sensors experience dramatic temperature swings during normal operation, creating significant pressure differentials that can stress sensor housings and affect measurement accuracy. The MicroVENT ePTFE membrane allows rapid pressure equalization, preventing the buildup of internal pressure that could damage delicate sensor components. This pressure relief capability proves particularly important for sensors in engine compartments where temperatures can fluctuate over 100 degrees Celsius during operation cycles.

The rapid gas exchange properties of the MicroVENT ePTFE membrane ensure that internal pressure tracks external atmospheric pressure changes, maintaining sensor calibration accuracy. Sealed sensors without proper venting often experience measurement drift as internal pressure changes affect sensing element behavior. The membrane's high air flow rate capabilities provide immediate pressure response, ensuring consistent sensor performance across varying environmental conditions. This pressure equalization prevents housing deformation that could affect sensor mounting and alignment.

Altitude and Atmospheric Pressure Variations

Modern vehicles operate across diverse altitudes and atmospheric conditions that create varying external pressures affecting sensor performance. The MicroVENT ePTFE membrane enables sensors to quickly equilibrate with changing atmospheric pressure, maintaining accurate readings regardless of elevation changes. This capability proves essential for altitude-compensated sensors that require precise atmospheric pressure references. The membrane's consistent permeability ensures predictable pressure equalization timing across temperature ranges.

Weather-related pressure changes can significantly impact unvented sensor readings, particularly for environmental monitoring applications. The MicroVENT ePTFE membrane provides controlled venting that allows sensors to track barometric pressure changes while maintaining protection from environmental hazards. This controlled atmospheric connection enables weather compensation algorithms to function properly, improving sensor accuracy and reliability. The membrane's stable properties ensure consistent venting performance throughout varying weather conditions.

Material Durability and Longevity

Temperature Resistance and Thermal Stability

Automotive applications demand materials capable of withstanding extreme temperature ranges without degradation or performance loss. The MicroVENT ePTFE membrane maintains its protective properties from -40°C to +125°C, covering the full range of automotive operating conditions. This thermal stability ensures consistent pore structure and permeability characteristics across temperature extremes. The material's low thermal expansion coefficient prevents stress-related failures during thermal cycling.

High-temperature exposure in engine compartments tests the limits of conventional protective materials, often causing brittleness or seal failure. The MicroVENT ePTFE membrane retains flexibility and integrity even after prolonged high-temperature exposure, maintaining effective sealing and barrier properties. The material's crystalline structure remains stable under thermal stress, preventing the dimensional changes that compromise seal effectiveness. This thermal durability translates to extended sensor protection throughout vehicle service life.

UV Resistance and Weather Exposure

Ultraviolet radiation degrades many polymeric materials, causing brittleness and loss of protective properties over time. The MicroVENT ePTFE membrane demonstrates excellent UV stability, maintaining its molecular structure and performance characteristics despite prolonged sunlight exposure. This UV resistance proves particularly important for sensors mounted in exterior locations where direct sunlight exposure occurs regularly. The material's inherent stability eliminates the need for UV stabilizers that could affect membrane permeability.

Weather exposure testing confirms the MicroVENT ePTFE membrane's ability to withstand rain, snow, salt spray, and temperature cycling without performance degradation. The membrane's hydrophobic properties prevent water absorption that could compromise structural integrity or filtration performance. Salt resistance ensures reliable performance in coastal environments and winter driving conditions where road salt exposure is common. This weather durability provides consistent sensor protection across diverse geographic and climatic conditions.

Installation and Integration Considerations

Mounting Methods and Seal Integrity

Proper installation of the MicroVENT ePTFE membrane requires careful attention to mounting techniques that maintain seal integrity while preserving membrane functionality. Compression sealing methods provide reliable attachment without damaging the delicate membrane structure. The membrane's flexibility accommodates slight housing irregularities while maintaining effective sealing around the perimeter. Proper installation procedures ensure optimal performance and prevent bypass leakage that could compromise protection.

Adhesive attachment options offer permanent mounting solutions for applications where removable access is not required. The MicroVENT ePTFE membrane's surface properties ensure excellent adhesive bonding while maintaining membrane integrity. Compatible adhesives provide long-term attachment reliability without affecting membrane permeability or filtration characteristics. Installation guidelines specify proper adhesive selection and application techniques for optimal results.

Housing Design and Membrane Placement

Sensor housing design significantly influences membrane performance and protection effectiveness. The MicroVENT ePTFE membrane functions optimally when positioned to minimize direct exposure to high-velocity water spray while maintaining atmospheric connection. Strategic placement behind baffles or in protected recesses enhances membrane longevity while preserving venting functionality. Housing geometry should provide adequate membrane area for required airflow while protecting against mechanical damage.

Membrane support structures prevent deflection under pressure differentials that could affect permeability or cause fatigue failures. The MicroVENT ePTFE membrane benefits from rigid backing support that distributes loads evenly across the membrane surface. Support perforation patterns must balance structural strength with minimal flow restriction to maintain optimal venting performance. Proper support design extends membrane service life while ensuring consistent protective capabilities.

Performance Validation and Testing

Laboratory Testing Protocols

Comprehensive testing validates the MicroVENT ePTFE membrane's performance across automotive operating conditions. Water ingress testing confirms barrier effectiveness under various pressure differentials and exposure durations. Standardized test methods evaluate membrane permeability, ensuring adequate airflow for pressure equalization while maintaining particle filtration efficiency. These controlled tests provide quantitative performance data for design validation and quality assurance.

Environmental chamber testing subjects the MicroVENT ePTFE membrane to accelerated aging conditions that simulate extended automotive service exposure. Temperature cycling, humidity exposure, and UV radiation testing verify long-term performance stability. Chemical compatibility testing confirms resistance to automotive fluids and cleaning agents. These comprehensive test protocols ensure reliable field performance under actual operating conditions.

Field Performance Validation

Real-world testing provides ultimate validation of the MicroVENT ePTFE membrane's effectiveness in actual automotive applications. Field trials monitor sensor performance and protection effectiveness across diverse operating environments and driving conditions. Long-term exposure studies track membrane performance degradation and identify potential failure modes. This field data validates laboratory testing results and provides confidence in membrane reliability.

Performance monitoring includes measurement of internal humidity levels, particle accumulation, and pressure equalization response times. These metrics quantify the MicroVENT ePTFE membrane's protective effectiveness and identify optimization opportunities. Comparative testing against alternative protection methods demonstrates superior performance characteristics. Field validation data supports membrane specification and application recommendations for optimal sensor protection.

FAQ

How does the MicroVENT ePTFE membrane compare to other protective options

The MicroVENT ePTFE membrane offers superior performance compared to traditional protective methods like rubber seals or plastic covers. Unlike solid barriers that trap moisture and pressure, the membrane provides selective permeability that allows pressure equalization while blocking contaminants. This dual functionality eliminates the compromise between protection and sensor performance that characterizes alternative solutions. The membrane's chemical inertness and temperature stability exceed the capabilities of most elastomeric sealing materials.

What maintenance requirements exist for ePTFE membrane protection

The MicroVENT ePTFE membrane requires minimal maintenance due to its self-cleaning properties and contamination resistance. The hydrophobic surface naturally sheds water and prevents fouling buildup that could compromise performance. Periodic visual inspection ensures membrane integrity and identifies any physical damage requiring replacement. The membrane's long service life typically matches or exceeds sensor replacement intervals, minimizing maintenance requirements.

Can the membrane withstand pressure washing and harsh cleaning

The MicroVENT ePTFE membrane demonstrates excellent resistance to high-pressure water spray and automotive cleaning chemicals. The microporous structure prevents water penetration even under direct pressure washing conditions. Chemical resistance ensures compatibility with degreasing agents and cleaning solvents commonly used in automotive maintenance. However, direct high-pressure spray should be avoided to prevent potential membrane damage or displacement.

How does temperature affect membrane performance and longevity

Temperature variations have minimal impact on MicroVENT ePTFE membrane performance within automotive operating ranges. The material maintains consistent permeability and barrier properties from sub-freezing to high-temperature engine compartment conditions. Thermal cycling actually enhances membrane performance by preventing pore blockage and maintaining optimal flow characteristics. The membrane's thermal stability ensures decades of reliable service without performance degradation or replacement requirements.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS