Estrutura de Poros Otimizada para Desempenho Aprimorado de Filtração

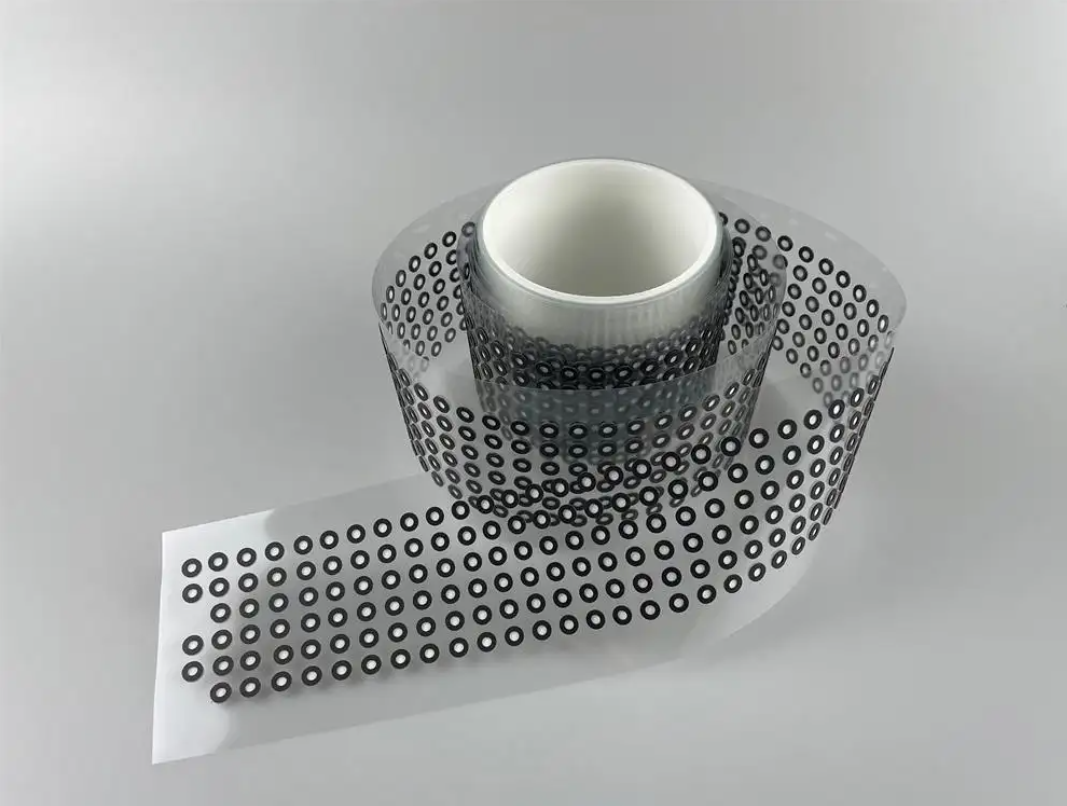

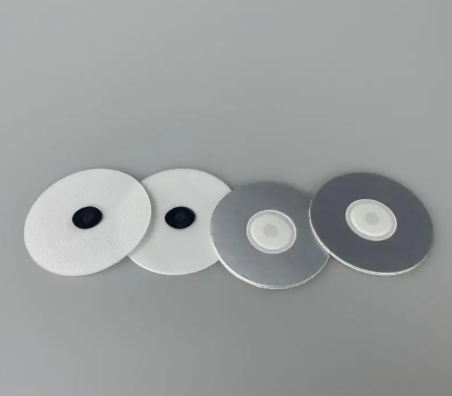

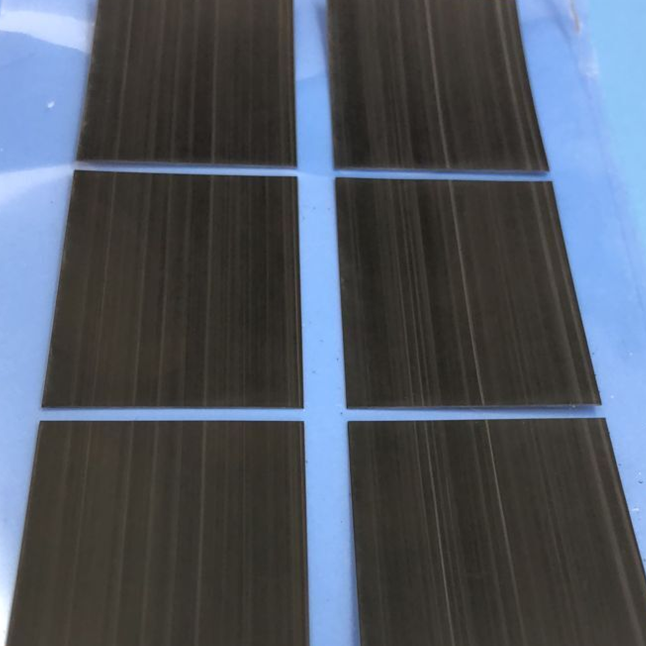

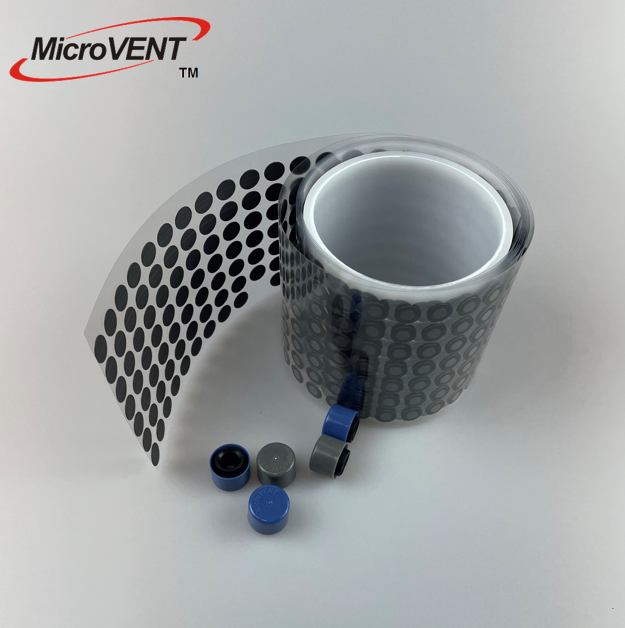

A membrana de ePTFE com LED apresenta uma estrutura microporosa projetada com precisão que oferece eficiência superior de filtração, mantendo ao mesmo tempo características de permeabilidade ideais para aplicações de alto desempenho. O processo de expansão controlada cria uma rede interconectada de nós e fibrilas com tamanhos de poros uniformes, que podem ser ajustados conforme requisitos específicos de filtração, desde a remoção de partículas submicrométricas até aplicações de separação de gases. Essa estrutura otimizada garante retenção consistente de partículas, minimizando a queda de pressão, o que resulta em economia de energia e maior eficiência do processo. A rede tridimensional de poros da membrana proporciona múltiplos caminhos de filtração, evitando entupimentos prematuros e prolongando os ciclos operacionais entre intervalos de limpeza. Os usuários experimentam um desempenho aprimorado na filtração por meio de taxas superiores de remoção de contaminantes, produtos finais mais limpos e redução nos requisitos de processamento posterior. A estrutura porosa da membrana de ePTFE com LED resiste à deformação sob pressão, mantendo características de filtração consistentes mesmo em aplicações de alta pressão, nas quais outras membranas poderiam se comprimir e perder eficácia. A rede de poros interconectados também facilita a limpeza e regeneração, permitindo que os usuários restaurem o desempenho da membrana por meio de procedimentos padrão de limpeza, em vez de exigir substituição completa. Esse design estrutural permite que a membrana suporte cargas variáveis de partículas sem degradação significativa do desempenho, oferecendo flexibilidade operacional em processos com níveis flutuantes de contaminação. A porosidade controlada assegura equilíbrio ideal entre seletividade e permeabilidade, permitindo a separação precisa de compostos-alvo enquanto mantém taxas adequadas de vazão. Aplicações em filtração de ar, processamento de líquidos e separação de gases se beneficiam da capacidade da membrana de manter cortes nítidos de peso molecular e características consistentes de retenção. A estrutura porosa da membrana de ePTFE com LED também contribui para suas excelentes propriedades de liberação de torta, prevenindo a incrustação irreversível e mantendo a eficiência de filtração a longo prazo em aplicações desafiadoras.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS