gorrência eptémica

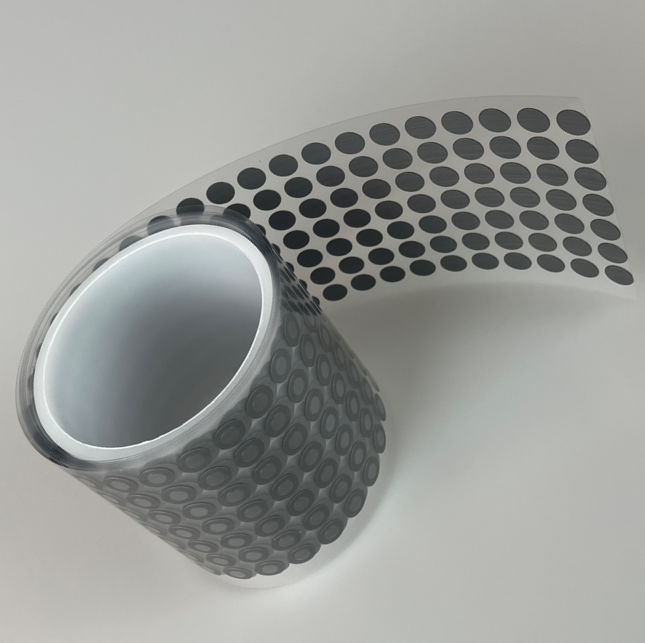

A membrana gore eptfe representa um avanço revolucionário na tecnologia de membranas, desenvolvida a partir de materiais de politetrafluoroetileno expandido (ePTFE) que oferecem desempenho excepcional em diversas aplicações industriais. Este sofisticado sistema de membrana combina respirabilidade com proteção impermeável, tornando-se uma solução ideal para filtração, roupas protetoras e aplicações em dispositivos médicos. A membrana gore eptfe possui uma estrutura microporosa única que permite a transmissão de vapor enquanto bloqueia a penetração de líquidos, criando uma barreira seletiva que mantém condições ambientais ideais. Os processos de fabricação envolvem o estiramento de materiais PTFE para criar porosidade controlada, resultando em membranas com tamanhos de poro precisos que variam de 0,1 a 50 mícrons, dependendo dos requisitos específicos da aplicação. A base tecnológica dos sistemas de membrana gore eptfe baseia-se na ciência avançada de polímeros, onde cadeias fluoradas de carbono conferem inércia química e estabilidade térmica. Essas membranas demonstram durabilidade notável em condições extremas, mantendo a integridade estrutural em faixas de temperatura que vão de -200°C a 260°C. A membrana gore eptfe exibe resistência química excepcional, permanecendo inalterada frente a ácidos, bases, solventes e outras substâncias agressivas que degradariam materiais convencionais de membranas. As aplicações abrangem inúmeras indústrias, incluindo aeroespacial, automotiva, eletrônica, farmacêutica e lazer ao ar livre, onde a proteção confiável por barreira é essencial. As propriedades hidrofóbicas da membrana garantem desempenho consistente em ambientes úmidos, enquanto suas características oleofóbicas proporcionam resistência a contaminantes à base de óleo. O controle de qualidade na fabricação assegura distribuição uniforme dos poros e espessura constante da membrana, oferecendo características de desempenho previsíveis entre diferentes lotes de produção. A tecnologia de membrana gore eptfe incorpora tratamentos superficiais especializados que aprimoram propriedades específicas, como resistência antimicrobiana ou características de adesão melhoradas. Essas membranas apoiam práticas sustentáveis de fabricação por meio de sua longevidade e reciclabilidade, reduzindo o impacto ambiental em comparação com alternativas descartáveis.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS