Pressure equalization in packaging systems represents a critical challenge across numerous industrial applications, from food preservation to pharmaceutical storage and electronic component protection. Modern packaging solutions demand sophisticated mechanisms that can maintain optimal internal conditions while preventing contamination and ensuring product integrity. The MicroVENT packaging valve has emerged as a revolutionary solution that addresses these complex requirements through advanced pressure-equalization technology, offering unprecedented control over internal package environments and extending product shelf life significantly.

Understanding Pressure Equalization in Modern Packaging

The Science Behind Pressure Differential Management

Pressure differentials occur naturally in sealed packaging environments due to temperature fluctuations, altitude changes, and product outgassing. These pressure variations can cause package deformation, seal failure, and compromised product quality. The MicroVENT packaging valve technology addresses these challenges by providing controlled pressure relief that maintains optimal internal conditions without compromising sterility or product integrity. This sophisticated approach to pressure management ensures consistent product quality across various environmental conditions and storage scenarios.

Traditional packaging methods often rely on rigid containers or flexible pouches that cannot adequately respond to pressure changes. The result is frequently damaged packaging, compromised seals, or products that deteriorate prematurely due to uncontrolled internal environments. Advanced valve technology transforms this paradigm by introducing intelligent pressure regulation that responds dynamically to changing conditions while maintaining the integrity of the sealed environment.

Critical Applications Requiring Pressure Control

Industries such as pharmaceuticals, food processing, electronics, and medical devices require precise environmental control within their packaging systems. The MicroVENT packaging valve serves these demanding applications by providing reliable pressure equalization that prevents package failure and maintains product efficacy. In pharmaceutical applications, pressure control ensures medication stability and prevents container deformation that could affect dosing accuracy. Food packaging benefits from pressure regulation that prevents spoilage while maintaining freshness and extending shelf life.

Electronic components are particularly sensitive to pressure variations, which can cause mechanical stress and component failure. The implementation of advanced valve technology in electronic packaging creates stable environments that protect sensitive components during shipping, storage, and handling. Medical device packaging requires the highest levels of sterility and protection, making pressure equalization an essential component of comprehensive packaging solutions.

Advanced Features and Technical Specifications

Precision Engineering and Materials Science

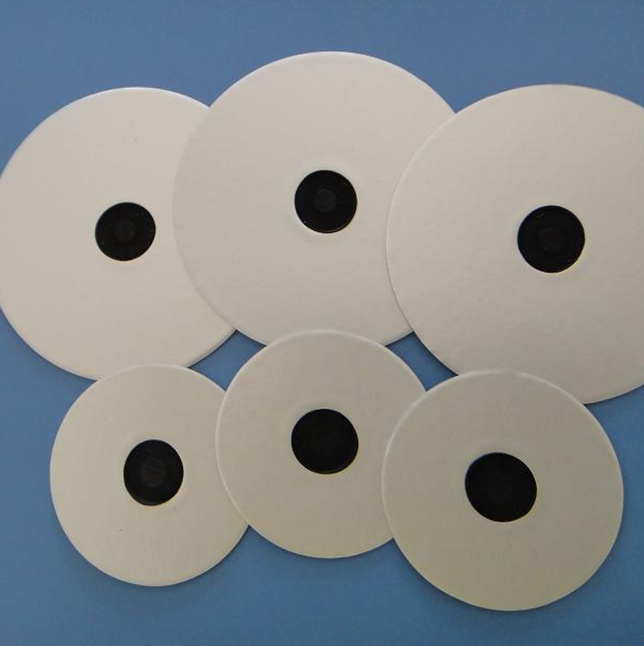

The engineering behind the MicroVENT packaging valve incorporates advanced materials science and precision manufacturing techniques to deliver consistent performance across diverse operating conditions. High-performance polymers and specialized membranes work together to create a valve system that responds predictably to pressure differentials while maintaining barrier properties against contaminants and moisture. The valve design includes multiple redundant sealing mechanisms that ensure reliability even under extreme conditions.

Manufacturing tolerances for these valve systems are measured in micrometers, ensuring consistent performance across large production runs. Quality control processes include comprehensive testing under simulated environmental conditions, including temperature cycling, humidity exposure, and mechanical stress testing. The result is a valve system that provides predictable performance throughout its operational lifetime, regardless of environmental challenges or handling conditions.

Integration with Existing Packaging Systems

Modern packaging operations require solutions that integrate seamlessly with existing production lines and quality control systems. The MicroVENT packaging valve is designed for easy integration with standard packaging machinery and processes, minimizing disruption to established workflows while dramatically improving package performance. Installation procedures are streamlined to reduce training requirements and implementation costs, making adoption feasible for operations of all sizes.

Compatibility testing ensures that valve systems work effectively with various packaging materials, from flexible films to rigid containers. This versatility allows manufacturers to implement pressure equalization technology across multiple product lines without requiring extensive equipment modifications or process redesign. The modular design approach enables customization for specific application requirements while maintaining standardized components and procedures.

Performance Benefits and Operational Advantages

Enhanced Product Protection and Shelf Life Extension

The primary benefit of implementing MicroVENT packaging valve technology is the significant improvement in product protection and shelf life extension. By maintaining optimal pressure conditions, these valve systems prevent package deformation that can compromise seals and allow contaminant ingress. Products remain fresh longer, reducing waste and improving customer satisfaction while providing significant cost savings through reduced returns and extended distribution capabilities.

Quantitative testing demonstrates that properly implemented valve technology can extend product shelf life by up to forty percent compared to conventional packaging methods. This improvement translates directly to reduced inventory turnover, expanded distribution networks, and improved profitability across the supply chain. The technology also enables manufacturers to reduce preservative levels in food products while maintaining safety and quality standards.

Cost Reduction and Operational Efficiency

Beyond product protection, MicroVENT packaging valve implementation provides substantial operational benefits through reduced packaging failures, lower return rates, and improved supply chain efficiency. Manufacturing operations experience fewer production interruptions due to packaging defects, while distribution networks benefit from reduced damage claims and improved product handling characteristics. These improvements contribute to overall operational efficiency and profitability.

Long-term cost analysis reveals that initial investment in advanced valve technology pays for itself through reduced waste, improved customer satisfaction, and expanded market opportunities. The technology enables manufacturers to enter new markets with confidence, knowing that their products will maintain quality and integrity throughout extended distribution chains and varying environmental conditions.

Implementation Strategies and Best Practices

System Design and Configuration

Successful implementation of MicroVENT packaging valve technology requires careful consideration of specific application requirements and operating conditions. System design begins with comprehensive analysis of product characteristics, environmental conditions, and performance objectives to determine optimal valve specifications and placement. Engineering teams work closely with packaging specialists to ensure that valve integration enhances rather than complicates existing processes.

Configuration parameters include pressure differential thresholds, response times, and environmental resistance requirements. These specifications are tailored to specific applications, ensuring that valve performance aligns precisely with product protection requirements and operational constraints. Testing protocols validate system performance under actual operating conditions before full-scale implementation begins.

Quality Control and Performance Monitoring

Ongoing quality control and performance monitoring are essential components of successful valve system implementation. Comprehensive testing protocols include pressure cycling tests, environmental exposure testing, and long-term stability assessments to ensure consistent performance throughout the product lifecycle. Real-time monitoring systems can provide immediate feedback on valve performance and alert operators to potential issues before they impact product quality.

Statistical process control methods track valve performance over time, identifying trends that might indicate the need for maintenance or adjustment. This proactive approach to quality management ensures that MicroVENT packaging valve systems continue to provide optimal performance throughout their operational lifetime, protecting product integrity and maintaining customer satisfaction.

Future Developments and Technology Evolution

Emerging Technologies and Integration Opportunities

The evolution of MicroVENT packaging valve technology continues to advance through integration with smart packaging systems and IoT connectivity. Future developments include intelligent valve systems that can communicate performance data, environmental conditions, and maintenance requirements through wireless networks. These advanced systems will enable predictive maintenance, real-time quality monitoring, and enhanced supply chain visibility.

Nanotechnology applications promise even more precise control over valve performance characteristics, with the potential for self-healing materials and adaptive response mechanisms. These emerging technologies will further enhance the reliability and effectiveness of pressure equalization systems while reducing maintenance requirements and operational complexity.

Sustainability and Environmental Considerations

Environmental sustainability represents an increasingly important consideration in packaging technology development. Future MicroVENT packaging valve designs incorporate biodegradable materials and recyclable components while maintaining performance standards. Life cycle analysis guides material selection and manufacturing processes to minimize environmental impact while maximizing product performance and longevity.

Sustainable packaging solutions that include advanced valve technology can significantly reduce food waste and product spoilage, contributing to overall environmental sustainability goals. By extending product shelf life and reducing packaging failures, these systems help minimize the environmental impact of manufacturing, distribution, and waste management processes throughout the supply chain.

FAQ

How does a MicroVENT packaging valve prevent package deformation

The MicroVENT packaging valve prevents package deformation by automatically equalizing pressure differentials that develop inside sealed packages due to temperature changes, altitude variations, or product outgassing. When internal pressure increases, the valve allows controlled air release, and when external pressure exceeds internal pressure, the valve permits controlled air entry, maintaining optimal pressure balance and preventing package distortion or seal failure.

What industries benefit most from MicroVENT packaging valve technology

Industries that benefit most from MicroVENT packaging valve technology include pharmaceuticals, food and beverage, electronics, medical devices, and specialty chemicals. These sectors require precise environmental control within packages to maintain product quality, prevent contamination, and ensure regulatory compliance. The valve technology is particularly valuable for products sensitive to pressure variations, moisture, or environmental contaminants.

Can MicroVENT packaging valve systems be integrated with existing production lines

Yes, MicroVENT packaging valve systems are specifically designed for seamless integration with existing production lines and packaging equipment. The modular design approach minimizes modifications to current processes while providing comprehensive training and support for implementation. Compatibility testing ensures successful integration with various packaging materials and machinery configurations without disrupting established workflows.

What maintenance requirements are associated with MicroVENT packaging valve systems

MicroVENT packaging valve systems require minimal maintenance due to their robust design and high-quality materials. Regular performance monitoring through quality control protocols helps identify any potential issues early. Preventive maintenance typically involves periodic inspection of valve components and verification of performance parameters, with most systems designed to operate reliably throughout their intended service life without significant intervention.

Table of Contents

- Understanding Pressure Equalization in Modern Packaging

- Advanced Features and Technical Specifications

- Performance Benefits and Operational Advantages

- Implementation Strategies and Best Practices

- Future Developments and Technology Evolution

-

FAQ

- How does a MicroVENT packaging valve prevent package deformation

- What industries benefit most from MicroVENT packaging valve technology

- Can MicroVENT packaging valve systems be integrated with existing production lines

- What maintenance requirements are associated with MicroVENT packaging valve systems

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS