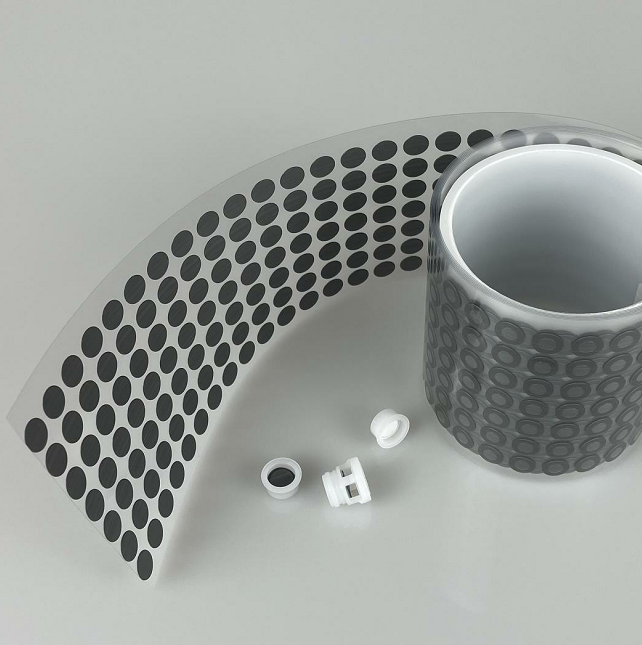

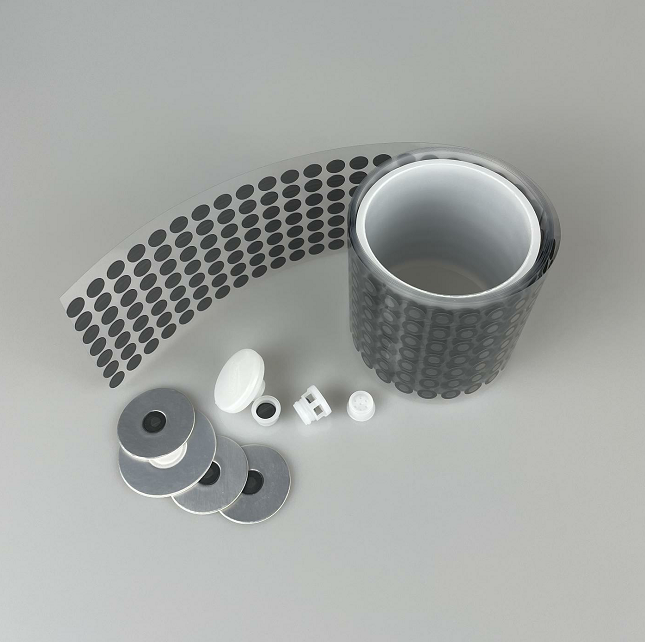

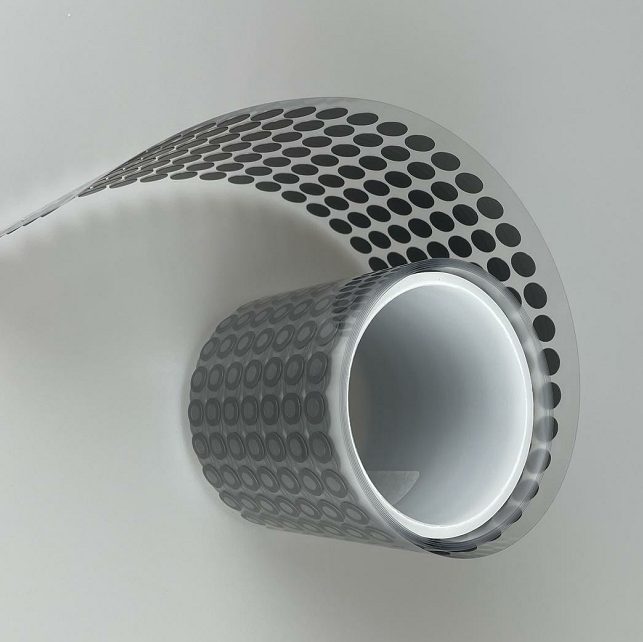

Penyegelan Efektif: Patch EPTFE memberikan segel yang andal yang mencegah kebocoran suara. Pada struktur dan perangkat, hal ini meningkatkan insulasi akustik.

Ketahanan: Patch ini dirancang untuk tahan terhadap aus dan robek, memastikan efektivitas jangka panjang serta ketahanan terhadap faktor lingkungan.

Mudah Dipasang: Patch ini sederhana dalam penerapannya, menjadikannya solusi yang ramah pengguna untuk insulasi suara dan penyegelan.

Hak Cipta © © 2025 Pan Asian Microvent Tech (Jiangsu) Corporation. Semua hak reserved. | Kebijakan Privasi