Vielseitige Anwendungen in verschiedenen Industrien

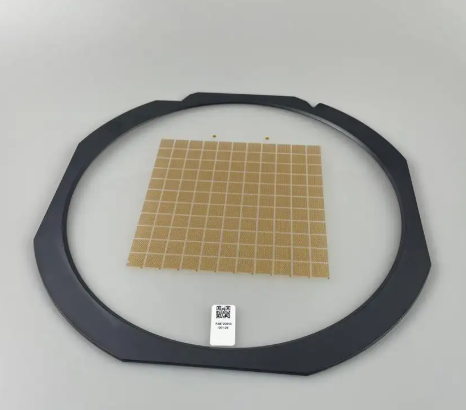

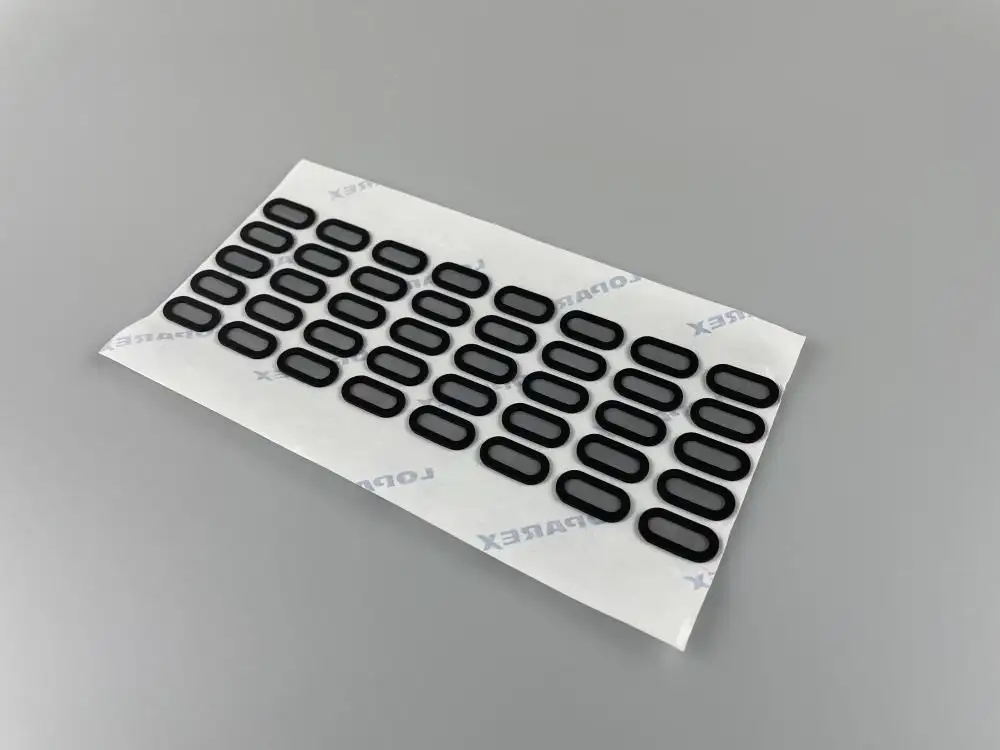

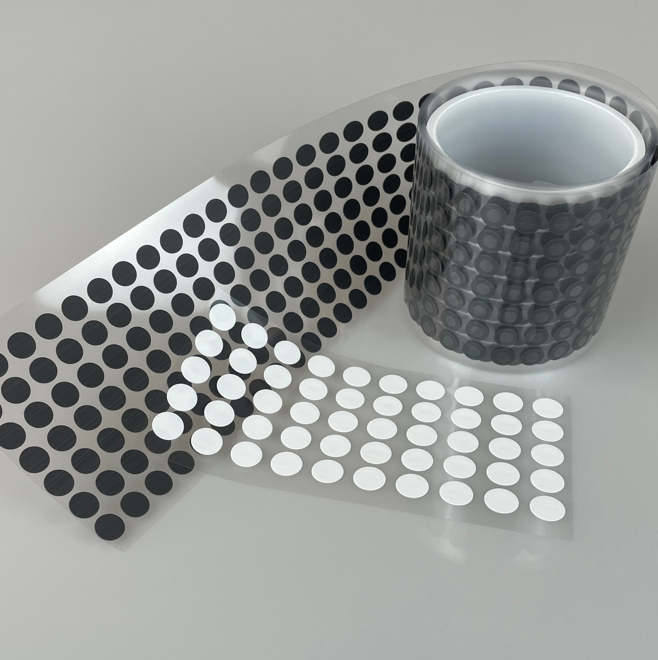

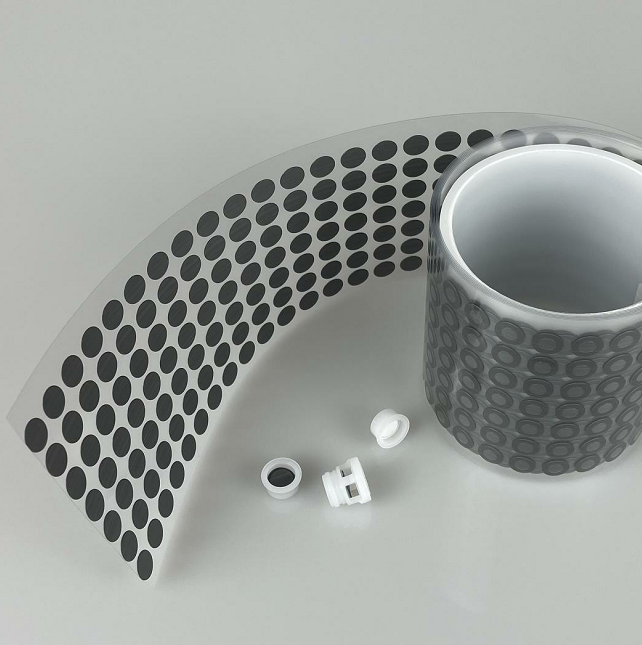

Das vielseitige Design und die hervorragenden Leistungseigenschaften des Nitto-Ventilfilters ermöglichen einen erfolgreichen Einsatz in einer breiten Palette von Industrien und Anwendungen, wodurch er zu einer wirklich universellen Filtrationslösung wird. Diese Anpassungsfähigkeit ergibt sich aus der Fähigkeit des Filters, unterschiedliche Betriebsbedingungen, Schadstoffarten und Leistungsanforderungen zu bewältigen, ohne dabei an Wirksamkeit einzubüßen. In der pharmazeutischen Produktion bietet der Nitto-Ventilfilter eine entscheidende Kontaminationskontrolle für sterile Produktionsbereiche, Reinräume und Lagerstätten. Die Fähigkeit des Filters, Sterilität aufrechtzuerhalten, während gleichzeitig eine notwendige Belüftung erfolgt, macht ihn unverzichtbar für die Einhaltung strenger behördlicher Vorschriften. Seine chemische Beständigkeit schützt vor Reinigungsmitteln und Desinfektionsmitteln, die üblicherweise in pharmazeutischen Anlagen verwendet werden. In der Lebensmittelverarbeitung profitiert man von der hygienischen Bauweise und der Widerstandsfähigkeit des Filters gegenüber Feuchtigkeit, Ölen und organischen Verbindungen. Die glatte Oberfläche verhindert das Wachstum von Bakterien und erleichtert eine gründliche Reinigung, sodass die Standards für Lebensmittelsicherheit gewahrt bleiben. Temperaturbeständigkeit ermöglicht den effektiven Einsatz des Filters sowohl in gekühlten als auch in beheizten Produktionsumgebungen. Chemische Industrien setzen auf die außergewöhnliche chemische Beständigkeit des Nitto-Ventilfilters, um aggressive Verbindungen sicher zu handhaben. Die Fähigkeit des Filters, Säuren, Laugen, Lösungsmittel und reaktive Chemikalien standzuhalten, macht ihn geeignet zum Schutz von Anlagen und Personal in gefährlichen Umgebungen. Druckausgleichsfunktionen verhindern gefährliche Druckerhöhungen in geschlossenen Systemen, während gleichzeitig die Kontaminationsbarrieren aufrechterhalten werden. In der Elektronikfertigung ist eine präzise Kontaminationskontrolle erforderlich, um empfindliche Bauteile vor Staub und Partikeln zu schützen, die Fehler oder Ausfälle verursachen könnten. Die feine Filtrationsfähigkeit des Nitto-Ventilfilters entfernt submikroskopisch kleine Partikel, die herkömmliche Filter nicht erfassen können, und gewährleistet so Produktqualität und Zuverlässigkeit. Eigenschaften zur Ableitung statischer Elektrizität verhindern elektrostatische Entladungen, die elektronische Bauteile beschädigen könnten. Automobilanwendungen umfassen Motorbelüftungssysteme, Getriebeentlüftung und Innenraumluftfiltration. Die Robustheit des Filters widersteht Vibrationen, Temperaturschwankungen und Kontakt mit Fahrzeugflüssigkeiten, während er über die gesamte Nutzungsdauer des Fahrzeugs eine konstante Leistung beibehält. Klima- und Lüftungsanlagen (HVAC) in Gewerbeimmobilien nutzen den Nitto-Ventilfilter, um die Innenraumluftqualität zu verbessern und gleichzeitig den Energieverbrauch durch geringe Druckverluste zu reduzieren. Die lange Standzeit des Filters verringert den Wartungsaufwand und die damit verbundenen Kosten bei großflächigen Installationen. Marine- und Offshore-Anwendungen profitieren von der Korrosionsbeständigkeit des Filters und seiner Fähigkeit, in feuchten, salzhaltigen Umgebungen zuverlässig zu funktionieren, in denen herkömmliche Filter schnell versagen.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS