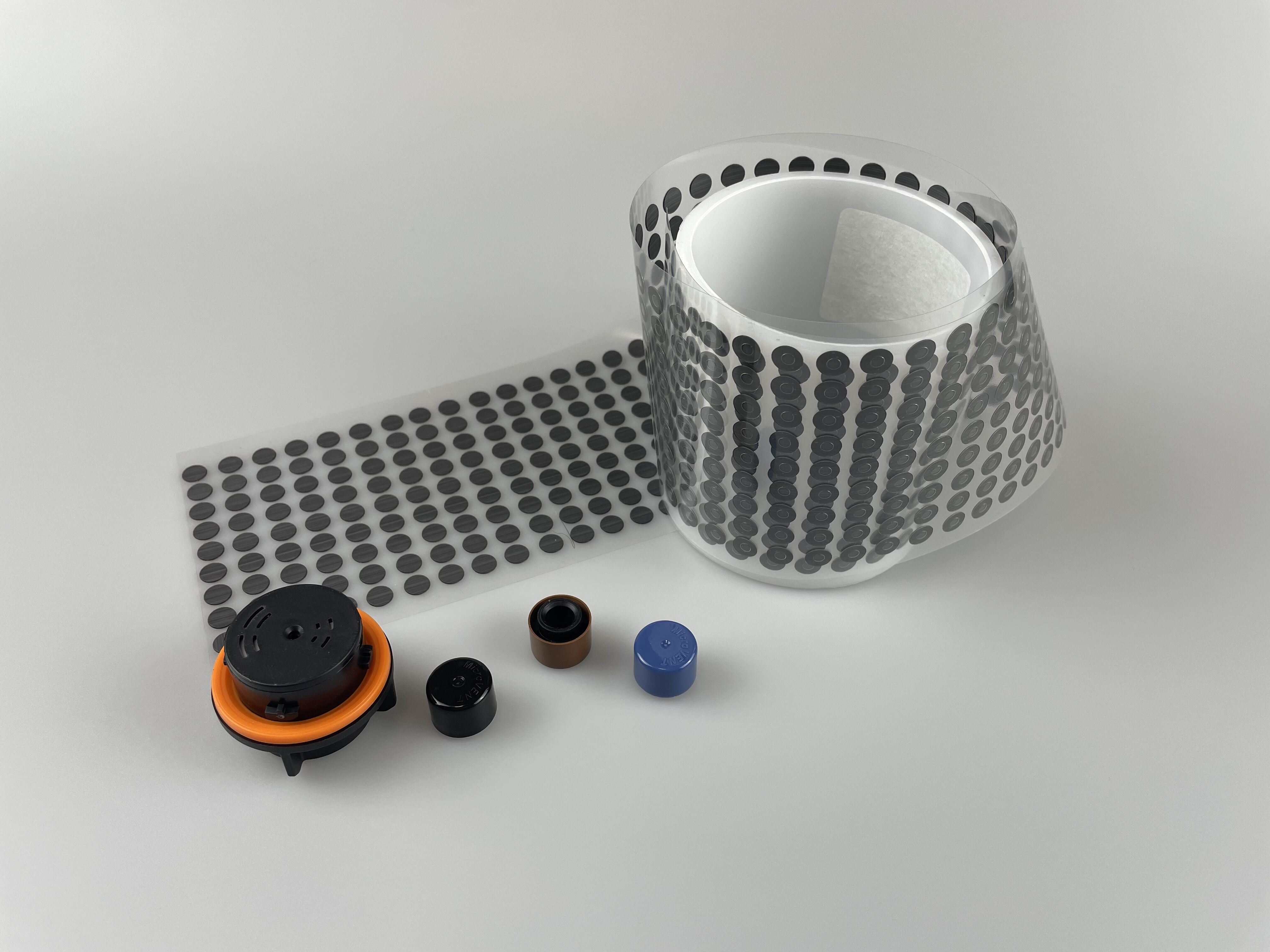

The packaging is a unique attribute of the chemical packers; it should be sealed properly and leakage proof. We will discuss if vent PE liners used as bottle caps can be enforced for your chemical applications concerning, not only the chemical resistance and functionality but also safety issues.

Understanding Vent PE Liners

Vent PE liners are composed of a durable, flexible polyethylene material. Those liners contain miniature faucets that balance the air pressure in a bottle. This will be a significant element to help keep the container from being exposed to loss of containment as you may subject a container to pressure drop as by temperature or altitude change.

Various PE Liners classified by their chemical resistance

Chemical resistance - one of the most important characteristics in chemical packaging is how resilient this liner is against chemical degradation. Polyethylene despite being one of the most stable chemical floats gives out very few chemicals and hence undergoes minimal oxidation. The material is fairly resistant to most acid, base and solvent product as found in chemical use. It ensures that the liner is protected from damage or interaction with content to keep the chemical intact.

Pressure Balance in Chemical Vessels

Chemical containers – subject to the same pressure changes influence that can deform or leak otherwise sealed environments These issues can be prevented by using vent PE liners that serve as a medium that allows the gas to enter and exit between the inner layer of the container and outside. Consequently, equalization of pressure is required so that the shape of your container in maintained and no harmful chemicals escape.

General conditions of safety and the environment

Chemical packaging is a safety sensitive area, vent PE liners have some built-in safety. They serve as a barrier against contamination, so that the chemical inside the bottle remains safe and uncontaminated. Moreover, PE materials are also highly resistant to chemicals and corrosion allowing them to store a variety of different chemical Products.

Vent PE liners must also meet safety regulations and environmental standards. With stringent industry regulations to meet, Baker an packaging ensures that the packing is safe both for the product and the end-user.

What Kind of Chemicals are okay to be put in Vent PE Liners?

Vacuum PE liners can be applied for numerous chemical usage. These are ideal for industrial chemicals (adhesives and coatings, agricultural chemicals like pesticides and fertilizers, additional household chemicals encompassing cleaners or detergents) PE liners are versatile and hence they find use in different segments of the chemical industry.

Difficulties in Chemical Use Cases

Although vent PE liners are great benefit in the applications of chemical, it can still be challenging. One drawback is compatibility with aggressive chemicals; certain reactive materials can cause liner material degradation with time. This is important for chemicals that have to be stored for long periods, since the stability and performance of the liner must be guaranteed over time.

Innovations and Advancements

Innovations in vent PE liner technology are continuing to help solve these issues. Custom-made liners are being developed with better resistance against chemicals and sealing abilities. This includes smart packaging technologies like indicators that change hues when the seal is breached.

Case Studies and Applications

There are multiple case studies available in literature that indicate the successful application of vent PE liners for chemical packaging. The studies have characterised the performance and safety outcome of the use of vent PE liners to demonstrate that they are able to contain chemicals in containers and prevent leaking. The actual uses these liners have been subjected to also yield further data on the performance of vent PE liners in chemical service conditions.

Upcoming Trends and Happenings

Future of vent PE liners in chemical applications.The future of vent PE liners for chemical applications will be formed by new materials and technologies. Two, material science may ultimately enable liners that resist chemistry over a wider range and last longer. Furthermore, going through regulatory changes might affect packaging solutions, and have a greater demand for advanced and compliant packing material.

Conclusion

In summary, vent PE liners can be adapted to a number of chemical applications where pressure equalization and chemical resistance (air vent below the liquid level) are critical. Although hurdles remain, especially with super-reactive chemistry, solutions are being developed to overcome these. The growing safety and compliance needs of chemical packaging will ensure an increasing demand for vent PE liners used in chemical packaging. Like the chemical industry, we will continue to push ourselves to develop new technologies that help meet the ever-changing packaging and safe transport/storage of chemical products.

Table of Contents

- Understanding Vent PE Liners

- Various PE Liners classified by their chemical resistance

- Pressure Balance in Chemical Vessels

- General conditions of safety and the environment

- What Kind of Chemicals are okay to be put in Vent PE Liners?

- Difficulties in Chemical Use Cases

- Innovations and Advancements

- Case Studies and Applications

- Upcoming Trends and Happenings

- Conclusion

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS