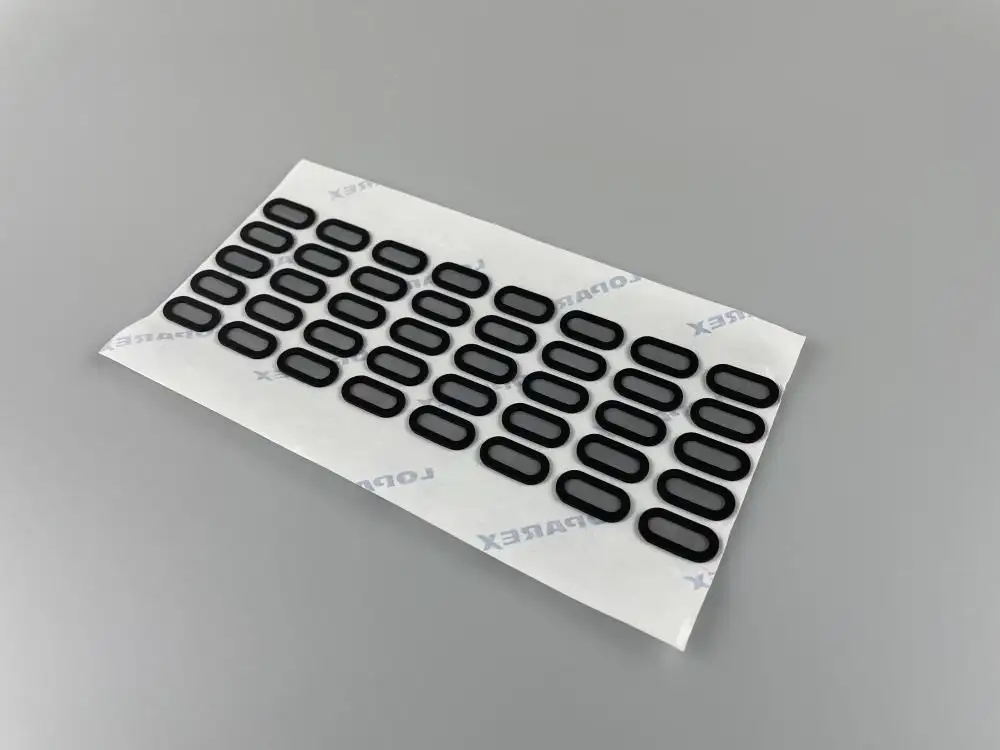

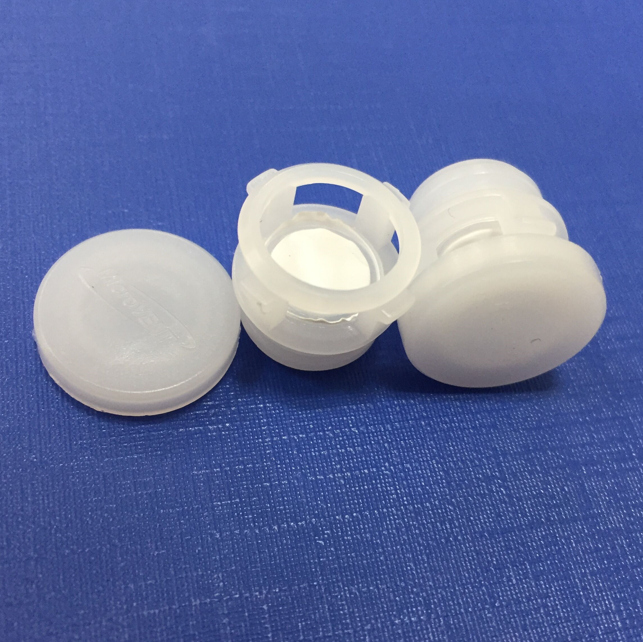

لماذا تستخدم الصناعات غشاء MicroVent®️ ePTFE للأضواء السيارات؟

منع التكثيف في أضواء السيارات باستخدام أغشية ePTFE العلوم المواد خلف توازن الضغط تشتهر أغشية ePTFE بقدرتها الاستثنائية على السماح بمرور الغازات بينما تمنع السوائل بشكل فعال على المستوى الجزيئي. هذا...

عرض المزيد

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS